INDUSTRIES WE CATER

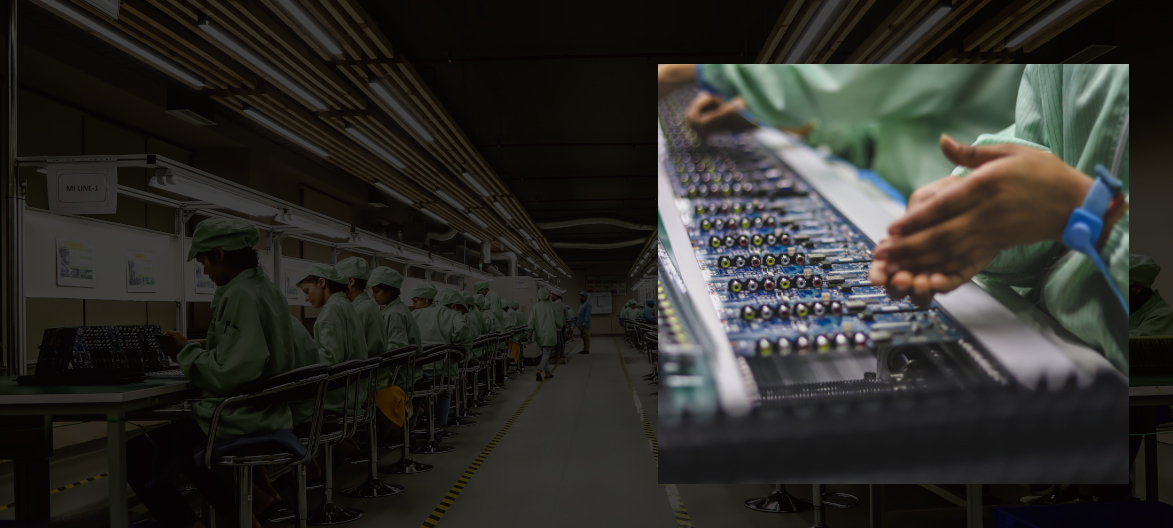

Make in India

By embracing Make in India, Surbhi Group ensures that our clients receive innovative, high-quality, and reliable electronic manufacturing solutions, all while contributing to India’s growth story

Advanced Manufacturing Technology

By staying at the forefront of technology, Surbhi Group ensures that our clients receive reliable, scalable, and cost-effective manufacturing solutions tailored to their business needs.

Awarded Telecom PLI

Proud to be a recipient of the prestigious Telecom Production Linked Incentive (PLI) benefits. This recognition underscores our commitment to driving innovation and excellence in the telecom manufacturing sector.

Quality driven Robust system

Our commitment to excellence is reflected in our best-in-class, quality-driven robust systems. Our robust systems ensure that every product leaving our facility embodies the quality, reliability, and innovation.

SURBHI SATCOM UNIT 2, SEC-155, NOIDA

CAPACITY : 20 lc UNIT / MONTH

KEY OFFERING

Flexibility and Adaptability

We prioritize flexibility and adaptability as core values that drive our success. We embrace change and foster a dynamic work environment where innovation thrives.

Continuous Improvement and Innovation

We are dedicated to refining our processes, enhancing efficiency, and introducing creative solutions that drive progress. we ensure that we not only meet but exceed customer expectations.

Quality Control

We are committed to maintaining the highest quality standards for all our products and services. Our robust Quality Control processes ensure that every product meets stringent guidelines.

Manufacturing Process

Our manufacturing process is designed to ensure precision, efficiency, and the highest quality standards. From raw material selection to final product inspection, we follow a streamlined approach that combines advanced technology with skilled craftsmanship.

Inventory Management

We implement the 5S Principles to create a more organized, efficient, and productive workplace. We also prioritize a clean room environment, ensuring all production areas meet stringent cleanliness standards.

Supply Chain Management

We carefully manage every stage of the supply chain, from sourcing raw materials to delivering finished products. By leveraging advanced technologies and maintaining strong relationships with suppliers and logistics partners, we ensure timely delivery, cost-effectiveness, and high-quality standards.

Quality Management

It is at the core of everything we do. We follow rigorous standards and best practices to ensure that every product and service meets the highest levels of quality. Our dedicated quality control teams conduct thorough inspections at every stage of production.

Lean System

Our inspection machines are seamlessly integrated with the Manufacturing Execution System (MES) to ensure a streamlined production process. This integration enables real-time data transfer, automating quality checks, and ensuring consistent monitoring of production lines.

Product Traceability Control

By integrating advanced inspection machines with our MES, we ensure end-to-end traceability across the production lifecycle. From raw material input to finished product delivery, every step is meticulously tracked, recorded, and analyzed.

Statistical Robust System

We take pride in our in-house expertise for designing and developing all processes, tooling, and fixtures locally. This capability ensures complete control over customization, quality, and efficiency, catering to the unique needs of our clients.

Our Blog

-

🌱 Plantation Drive at Surbhi With the belief that every small step towards nature creates... Read More

-

Health Checkup At Surbhi

Health Checkup At Surbhi 💙 At Surbhi, health isn’t an event — it’s our culture.... Read More -

Women’s Day Celebration

🌸 Empowering Women, Celebrating Strength! 🌸 We honor the dedication, resilience, and contributions of the... Read More -

Team Outing

A day out with Surbhi fam!We believe a fun way can facilitate team bonding and... Read More -

Enhancing & Expanding Limits

Enhancing capacity in highly automated #SMT lines which will reduce overall production costs by making the factory... Read More -

Bidding Farewell

As your journey with Surbhi Group comes to a close, we want to take a... Read More -

Awarded Telecom PLI

Proudly selected under Electronics PLI Scheme For Manufacturing launched by H’ble PM Narendra Modi -

IATF & OHSAS Certifications 2021

These certifications reinforce Surbhi Group’s position as a trusted partner for delivering high-quality electronic manufacturing... Read More -

Qualified under PLI Scheme

A proud moment for Surbhi Satcom Pvt Ltd to be qualified under PLI Scheme for... Read More

Hearables & Wearables

Design & Prototyping

Develop prototypes to test the design and functionality. Iterate on the design based on user feedback and testing results.

PCB & Assembly

Assemble the various components, taking care to ensure proper alignment and connectivity.

Implement efficient assembly processes to streamline production. Integrate the battery into the device, ensuring proper placement and secure connections.

Quality Control and Testing

Perform thorough functional testing to ensure that all components work as intended.

Check for defects, misalignments, or any issues that may affect performance or user experience.

Conduct testing for wireless connectivity and signal strength.

Final Enclosure & Software Integration

Assemble the final enclosure, ensuring a secure fit and proper alignment of all components.

Attach any external elements such as buttons, ports, or indicators. Load or install the necessary firmware and software onto the device.

Test the software in conjunction with the hardware to ensure seamless functionality.

Final Inspection & Packaging

Conduct a final inspection to verify that the device meets design specifications and quality standards.

Check for cosmetic issues and ensure all features are working correctly.

Package the hearable in its final retail packaging, including user manuals and accessories.

Apply branding and labeling as necessary.

Testimonial

We are very satisfied with the services provided by Surbhi. Our partnership has been a great success.

HI-FOCUSIt is to certify that we have been using SURBHI Cables, Connectors & Jumpers for various GSM Projects. The quality of the material found to be satisfactory.

VODAFONEI have had the great pleasure of working with Surbhi Group for the past 2 Years. They have been responsible for building PCBA for our Smart LED TV.

MICROMAXOn behalf of RCBS Digital, I thank you for all of your hard work and outstanding contributions in recovering unclaimed funds. It’s great to know that we can count on you to go the extra mile.

RCBSWe are pleased to inform you that IBS material (omni, Patch Panel, Splitter, Couplers, Jumper and R.F Cables) Supplied by SURBHI to various sites for our LTE projects has performed technically good to our satisfaction.

AIRTELI have had the great pleasure of working with Surbhi Group for the past 2 Years. They have been responsible for building PCBA for our Smart LED TV.

BRIGHTWAY